MAC Chain and Gear Lubricant

Categories: Lubricants, Industries, Engineering, Food Manufacturing, Forestry, Bulk

MAC Chain and Gear Lubricant

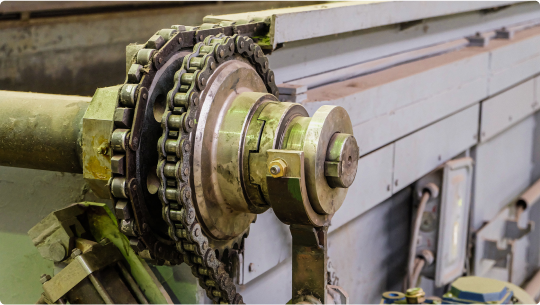

MAC Chain and Gear Lubricant 20L is a heavy-duty lubricant formulated for optimal protection and smooth operation of industrial chains, gears, wire ropes, and moving equipment.

Engineered for harsh NZ conditions, this high-performance lubricant reduces friction, prevents wear, and resists water washout.

MAC Chain and Gear Lubricant delivers reliable, long-lasting lubrication for demanding chain and gear systems across New Zealand industry.

- Heavy duty chain & gear lubricant

- Penetrates quickly, non-drying, waterproof lubricating film

- Deeply penetrates between wire strands, chain links, pins, rollers and sprockets

- Excellent adhesion properties (won’t sling off)

- Withstands high pressure and shock loads

- Resistant to water, steam, salt water and heat

- Performs from -30 to 180°C

- Available in 20L or 200L drums and 500ml aerosol

- Made in New Zealand

Find Nearest Stockist

Stock#

EXTTU002

Variant/Size

2 UNITS/PK

Quantity

6

Gr.Wt (Kg)

Vol (m3)

Details

Applications

Use in conjunction with CanGun1

Ideal for insecticides, lubricants and degreasers - getting the product exactly where you need it

Simple easy to adopt system with excellent fine mist product dispersal

Frequently Asked Questions

Precision Spray Accessory for Efficient, Clean Application

Aerosol Extension Tube 2-Pack is a practical accessory designed to deliver targeted, controlled spraying for a variety of aerosol products. Whether you are using insecticides, lubricants, degreasers, or cleaning solutions, these extension tubes make it easy to reach confined or awkward spaces, ensuring that the product goes exactly where it is needed. The design is compatible with most standard aerosol cans and fits securely with the CanGun1 ergonomic spray handle, a popular choice for both professional and DIY users across New Zealand. By attaching an extension tube, you can apply sprays under floors, behind pipes, inside machinery, or along ceiling edges with minimal overspray or waste.

Precision delivery helps reduce mess, saves product, and improves user safety by keeping hands away from treated surfaces or hazardous areas. This makes the Aerosol Extension Tube 2-Pack especially valuable for pest control, automotive maintenance, engineering, industrial cleaning, and property management. Insecticides and lubricants, in particular, benefit from the fine, directed spray that these tubes allow, making it easier to treat nests, hinges, or moving parts without affecting surrounding materials. Extension tubes are a staple for facilities maintenance teams and professionals who need reliable, effective coverage in hard-to-access locations. For general guidance on safe use and storage of aerosols in New Zealand, see EPA NZ’s aerosols page.

Aerosol Extension Tube 2-Pack is a practical accessory designed to deliver targeted, controlled spraying for a variety of aerosol products. Whether you are using insecticides, lubricants, degreasers, or cleaning solutions, these extension tubes make it easy to reach confined or awkward spaces, ensuring that the product goes exactly where it is needed. The design is compatible with most standard aerosol cans and fits securely with the CanGun1 ergonomic spray handle, a popular choice for both professional and DIY users across New Zealand. By attaching an extension tube, you can apply sprays under floors, behind pipes, inside machinery, or along ceiling edges with minimal overspray or waste.

Precision delivery helps reduce mess, saves product, and improves user safety by keeping hands away from treated surfaces or hazardous areas. This makes the Aerosol Extension Tube 2-Pack especially valuable for pest control, automotive maintenance, engineering, industrial cleaning, and property management. Insecticides and lubricants, in particular, benefit from the fine, directed spray that these tubes allow, making it easier to treat nests, hinges, or moving parts without affecting surrounding materials. Extension tubes are a staple for facilities maintenance teams and professionals who need reliable, effective coverage in hard-to-access locations. For general guidance on safe use and storage of aerosols in New Zealand, see EPA NZ’s aerosols page.

The Aerosol Extension Tube 2-Pack includes two durable, lightweight extension tubes engineered to work seamlessly with the majority of aerosol can products on the New Zealand market. Each tube is constructed from high-quality, chemical-resistant plastic, designed to withstand use with a wide range of products, including insecticides, degreasers, and lubricants. The tubes offer flexibility and strength, allowing them to bend or angle as needed without breaking or kinking. This adaptability is ideal for spraying in difficult locations, such as beneath appliances, along window tracks, or within automotive engines.

Simple to install, the extension tubes press-fit securely onto most spray nozzles and can be easily swapped or cleaned between uses. When used with an ergonomic spray handle like the CanGun1, they provide even greater comfort and reduce user fatigue during longer tasks. By directing spray into targeted areas, these extension tubes reduce the risk of product drifting into unwanted zones, which helps protect nearby surfaces, improves environmental safety, and minimises clean-up. They are suitable for use in homes, workshops, food production facilities, commercial kitchens, and manufacturing plants throughout NZ.

Regular use of extension tubes can extend the lifespan of aerosol cans by reducing wasted product and helps users maintain precise, professional results. For best results, always check compatibility with your specific can and store tubes in a clean, dry place after use.

The Aerosol Extension Tube 2-Pack includes two durable, lightweight extension tubes engineered to work seamlessly with the majority of aerosol can products on the New Zealand market. Each tube is constructed from high-quality, chemical-resistant plastic, designed to withstand use with a wide range of products, including insecticides, degreasers, and lubricants. The tubes offer flexibility and strength, allowing them to bend or angle as needed without breaking or kinking. This adaptability is ideal for spraying in difficult locations, such as beneath appliances, along window tracks, or within automotive engines.

Simple to install, the extension tubes press-fit securely onto most spray nozzles and can be easily swapped or cleaned between uses. When used with an ergonomic spray handle like the CanGun1, they provide even greater comfort and reduce user fatigue during longer tasks. By directing spray into targeted areas, these extension tubes reduce the risk of product drifting into unwanted zones, which helps protect nearby surfaces, improves environmental safety, and minimises clean-up. They are suitable for use in homes, workshops, food production facilities, commercial kitchens, and manufacturing plants throughout NZ.

Regular use of extension tubes can extend the lifespan of aerosol cans by reducing wasted product and helps users maintain precise, professional results. For best results, always check compatibility with your specific can and store tubes in a clean, dry place after use.

To use the Aerosol Extension Tube 2-Pack, simply insert the tube firmly into the spray head of your chosen aerosol can, ensuring a secure fit. If you are using the CanGun1 trigger accessory, attach the extension tube as per the handle’s instructions. Aim the nozzle toward the area requiring treatment and press to spray, adjusting your distance as needed to achieve the desired coverage. Always follow the safety instructions provided with your aerosol product, including wearing appropriate personal protective equipment (PPE) if recommended by the manufacturer.

After use, remove the extension tube and, if necessary, rinse with warm water or an appropriate solvent to clear any product residue. Allow to dry completely before reusing or storing. Inspect the tubes regularly for blockages or damage and replace if they show signs of excessive wear. Keeping tubes clean and free of obstructions ensures reliable performance and helps prevent clogging of the spray nozzle.

The Aerosol Extension Tube 2-Pack is intended for single or repeated use, depending on the chemical being sprayed and user preference. For health and environmental safety, do not leave tubes attached to cans during long-term storage, and keep out of reach of children.

For a complete selection of spray accessories, view Arandee’s full Accessories range.

To use the Aerosol Extension Tube 2-Pack, simply insert the tube firmly into the spray head of your chosen aerosol can, ensuring a secure fit. If you are using the CanGun1 trigger accessory, attach the extension tube as per the handle’s instructions. Aim the nozzle toward the area requiring treatment and press to spray, adjusting your distance as needed to achieve the desired coverage. Always follow the safety instructions provided with your aerosol product, including wearing appropriate personal protective equipment (PPE) if recommended by the manufacturer.

After use, remove the extension tube and, if necessary, rinse with warm water or an appropriate solvent to clear any product residue. Allow to dry completely before reusing or storing. Inspect the tubes regularly for blockages or damage and replace if they show signs of excessive wear. Keeping tubes clean and free of obstructions ensures reliable performance and helps prevent clogging of the spray nozzle.

The Aerosol Extension Tube 2-Pack is intended for single or repeated use, depending on the chemical being sprayed and user preference. For health and environmental safety, do not leave tubes attached to cans during long-term storage, and keep out of reach of children.

For a complete selection of spray accessories, view Arandee’s full Accessories range.